Welcome to SorTek website !

Welcome to SorTek website !

Application

SorTek high frequency screen is with high efficiency, small amplitude, and high separated frequency. It' s different from the common separating equipment in the working principles.Because of the high frequency. It destroys the tension of the mash surface and high speed vibrating of the fine material on the screen ,speeds the useful material and separated effect of the high density and increase the probability of the smaller separate granularity.

Technology

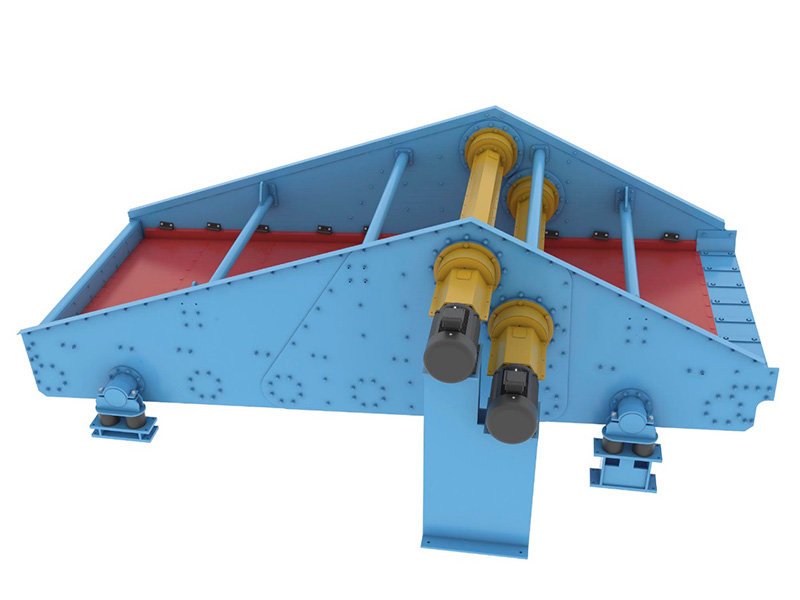

SorTek series linear vibrating screen is designed with reference to the structure of the GERMAN KHD company USL screen machine and absorbs the advanced technology of the American and Japanese sieve machines. Widely used in coal, mining, metallurgy, chemical, food, building materials and other industries, the medium and fine-grained materials for dry and wet grading or dehydration, deregulation and desludation and other operations. It can also replace the ZSM double-shaft vibrating screen for coal briquettes during the renovation of the old plant. The vibrating screen has high vibration intensity, strong processing capacity, high screening efficiency, simple structure, smooth operation, low noise and long service life.

The vibrator adopts self-synchronous vibrator, which has a low failure rate compared to the vibration motor, large excitation force, long service life and stable working; The bearings are uniformly stressed, and the ring grooves are coldly riveted to form a frame structure. It has the characteristics of advanced structure, high vibration frequency, large processing capacity, good screening effect, convenient maintenance, and robustness.

Features

■The use of unit combination block eccentric vibrator, easy to serialize, strong versatility.

■The application of self-synchronization principle, no gear forced dragging, the movement trajectory according to the linear type, light weight, reliable work, low noise, small maintenance.

■The beam and sieve box adopt riveted structure, and the side plate does not have any weld seam, which avoids welding stress and prevents the cracking of the side plate. In the area where the side plate is under a large force, the guard plate and the reinforcement ribs are reasonably arranged to effectively increase the strength of the side plate. All angle steels and skid plates are connected to the side plates by cold riveting technology to avoid assembly welding stresses.